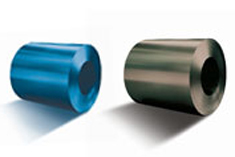

COIL CENTER

Coil slitting services with the closest tolerances Custom steel processing services and parts manufacturingHot-dip Galvanized Iron (HGI)

HGI is produced by hot rolled steel (HR) and it is processed through the acid washing and rolling process in zinc. HGI has strong corrosion resistance and high cost-efficiency. It is commonly used in construction material, pipes, guardrails

Galvanized Iron / Galvanized Steel sheet (GI)

GI is made by cold rolled steel (CR) and processed through zinc galvanized on the surface by dipping in a zinc pot. It has superior corrosion resistance and can easily be painted on.

Read more

Electro Galvanized Iron (EGI)

EGI is produced by CR steel coil and it is galvanized through electric or electrolyte to enhance corrosion resistance. It has low thickness of zinc plating and uniformity. EGI is hardly affected by heat when it is galvanized, therefore, it can maintain the mechanical properties for high processability, weldability, paint-ability, corrosion resistance

Read more

Galvalume

Galvalume is a coating consisting of zinc, aluminum and silicon. The three elements; aluminum, zinc and silicon are ideally combined: aluminum of 55%, zinc of 43.4%, silicon of 1.6%. It is like galvanizing in that it is sacrificial metal coating which protects the base metal. Galvalume has advantages of aluminum and zinc, possessing both superior corrosion resistance and heat-resisting property.

Read more

Tin Plate

Tin plate consists of sheets of steel, coated with a thin layer of tin. It has 0.14 ~0.60(mm) thickness and cold rolled steel is mainly used for producing tin plate as base metal. Possessing both glossy surfaces and corrosion resistance makes tin plates highly processable. Processability is the main reason why it is used in items related to food containers, like canned foods.

Read more

Color Steel Sheet

Steel sheets are offered in a wide variety of colors. Moreover, any of our base metals can be powder coated to the color of your choice and various patterns and textures.

Cold Rolled Steel Sheet

CR steel is essentially hot rolled steel that has undergone further processing. It is processed to a 40% reduction in thickness. It has excellent machinability and flatness. It commonly used in automobile and electric products.

Read more

Galvannealed Steel Sheet (GA)

GA steel plate uses high frequencies to apply high temperatures in short periods of time with heating furnaces and soaking furnaces that processes long term heats. It can completely prevent irregular patterns of alloys near the edge and powdering during forming, which are major disadvantages of the existing gas firing facility products.

KR

KR