FAST DEPLOYMENT

Lighter than concrete barriers

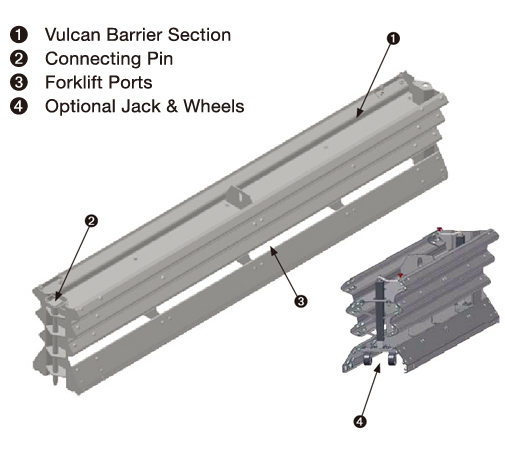

Free standing Anchorless Optional wheels

LONG LIFESPEND

20 years VS 3-5 years

Waterfilled / Concrete Barriers

HIGHT CONTAINMENT

Tested to NCHRP TL 3 & 4

Deflection : 1.9M

KR

KR