Smart Farm / Greenhouse

Shinsung Control develops economic and efficient smart-farm technologies.Greenhouse

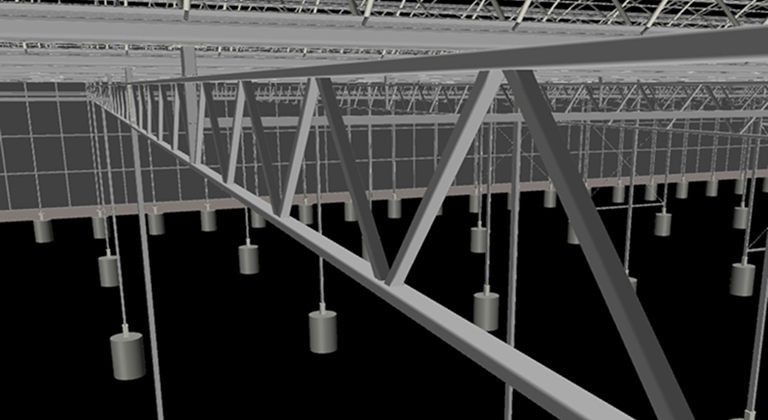

Hybrid Technology Applied

Roof: PO film (vinyl) / Sidewalls: Multi-layer PC panels

-

- Durability and Lifespan

- Vinyl

Prone to damage from UV exposure, wind, snow, and rain; typically requires replacement every 2–4 years - PC (Multi-layer) Panels

Highly impact-resistant and weather-resistant, offering a lifespan of more than 10 years

-

- Structural Stability

- Vinyl

Extensive reinforcement structures are required as vinyl is vulnerable to wind and snow loads - PC (Multi-layer) Panels

With high material rigidity (strength + stiffness), PC panels provide excellent structural stability on their own

-

- Thermal Insulation Performance

- PC (Multi-layer) Panels

PC panels can be manufactured in multiple layers (double- or triple-wall), significantly reducing heat loss. This greatly improves heating efficiency in winter and can also provide UV-blocking functionality during summer

-

- Light Transmittance & Crop Growth

- Vinyl

Vinyl has high initial light transmittance, but it rapidly declines over time due to contamination and discoloration - PC (Multi-layer) Panels

With UV-blocking coatings and light-diffusion performance, PC panels provide uniform light distribution, enabling stable and healthy crop growth

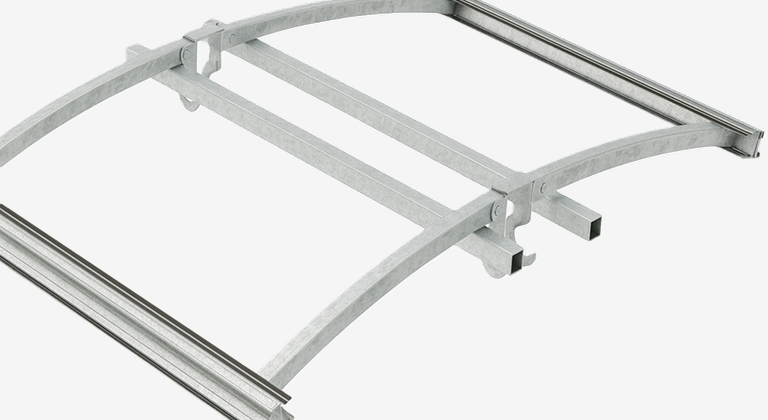

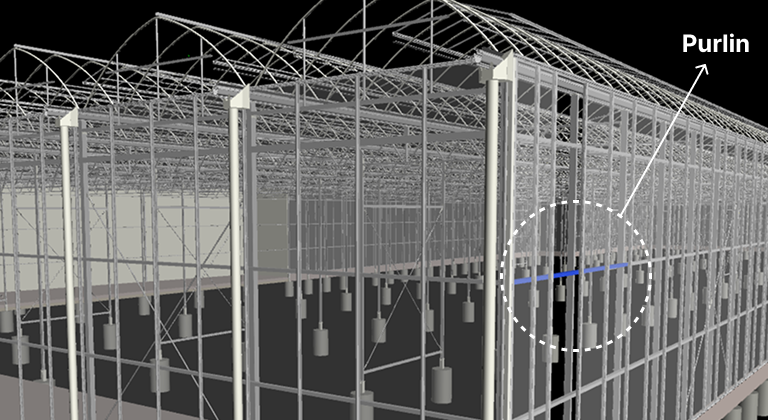

Structural Optimization Technology

-

- Truss cross-bracing and BIM-based design

-

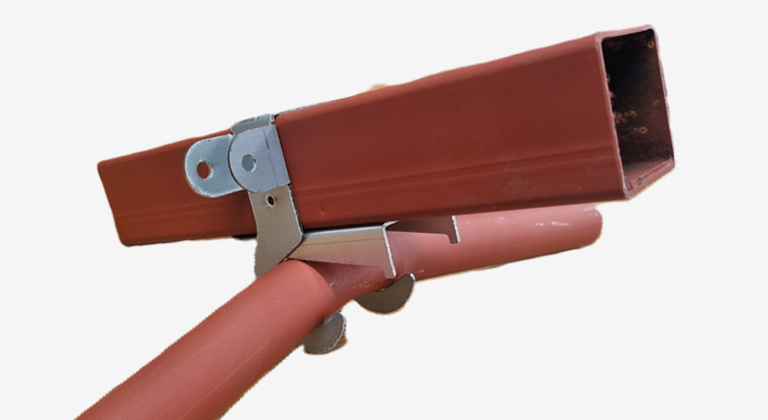

- Clamp fastening

-

- Gutter systems

-

- Bending performance through purlin spacing

-

- Enhanced structural stability

- Maintained Tension

Applies proper tension to keep the vinyl tight, preventing sagging and the formation of water pockets - Resistance to Wind & Snow Loads

A taut membrane distributes loads evenly, reducing the risk of localized tearing. Snow also slides off more easily before accumulating

-

- Improved Internal Environment Control

- Temperature & Humidity Retention

Proper tension improves airtightness, enhancing heating efficiency by limiting outside air infiltration - Reduced Condensation & Dripping

A flat, tensioned vinyl surface channels water droplets to the sides, preventing them from falling directly onto crops

-

- Reduced Maintenance Costs

- Extended Lifespan

Stable tension minimizes wind-induced fluttering, reducing material wear - Longer Replacement Cycles

Less tearing or damage results in extended vinyl replacement intervals

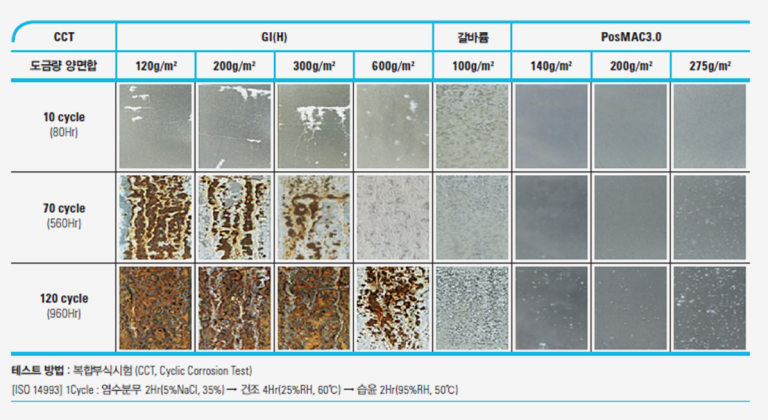

Use of POSMAC Steel

-

- High-corrosion-resistance steel optimized for greenhouse environments

-

- The flat-surface corrosion resistance of POSMAC 3.0 is 5–10 times superior to that of conventional hot-dip galvanized steel sheets

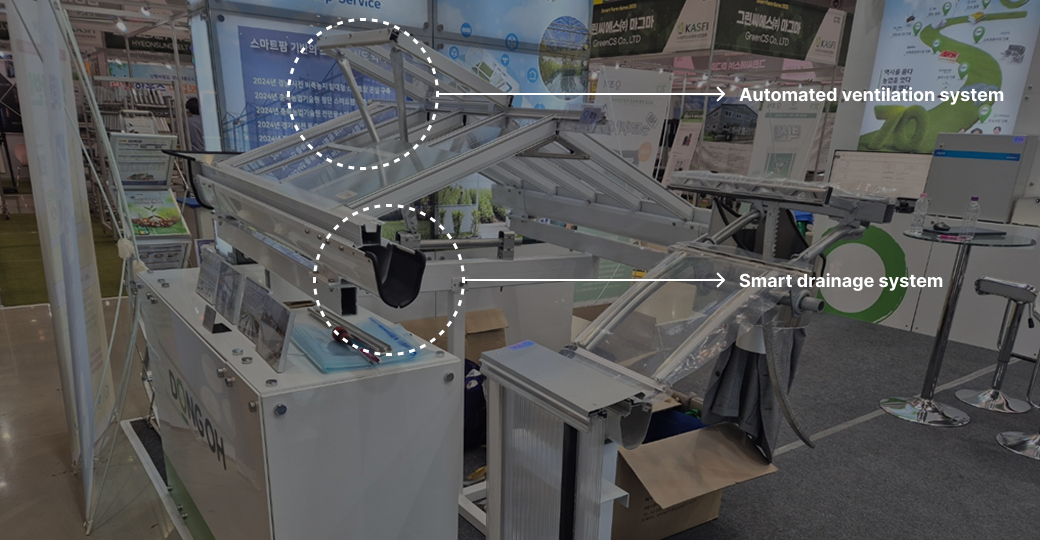

Ventilation and Drainage Systems

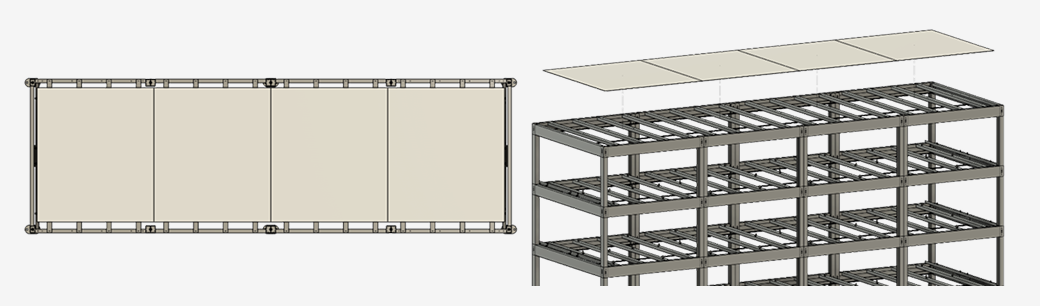

Vertical Cultivation Rack

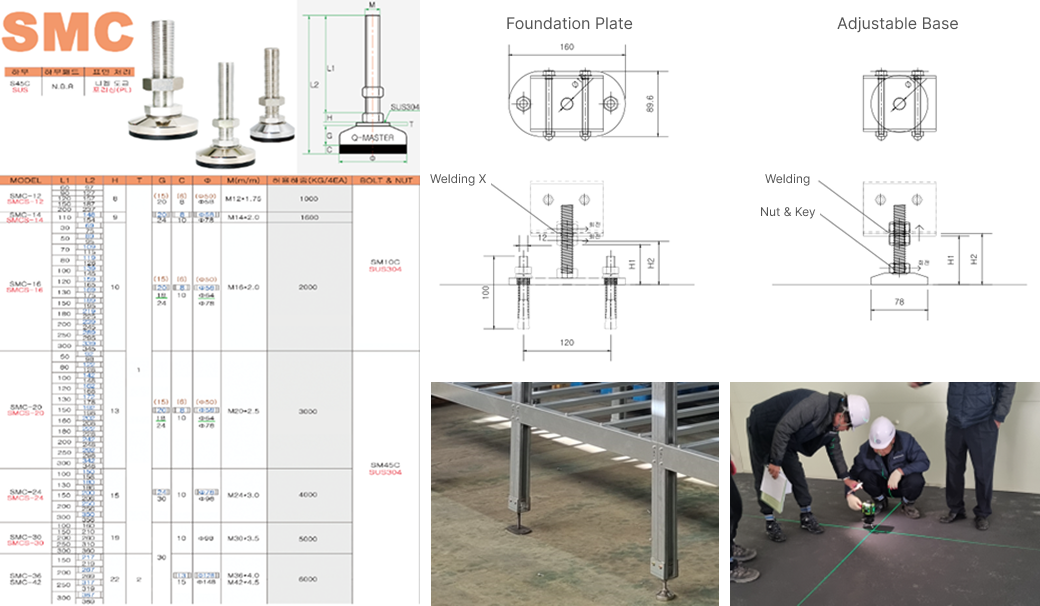

Columns and Adjustable Bases

Corner-Fixed Foundation Anchor: Prevents lateral shaking (left–right movement) / Improves anti-torsion resistance when a rental cart or equipment collides

Adjustable Base: Enables fine height adjustments (up and down)

Connection Method

Enhanced fastening strength and horizontal precision through boltless connections combined with screw fastening (dual method)

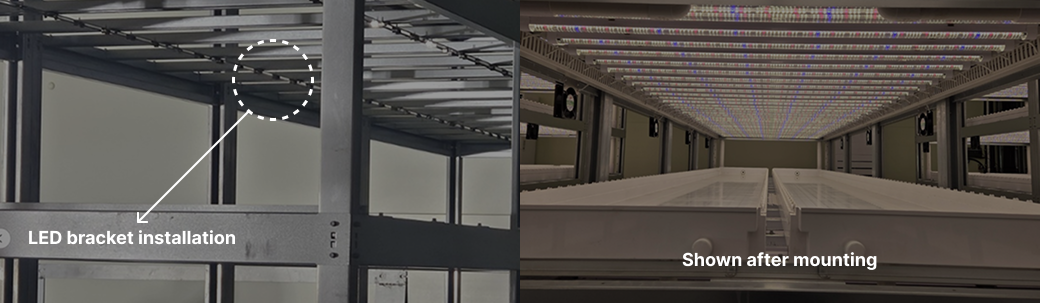

Dedicated LED Mounting Bracket

Easy fastening method with improved fixation strength

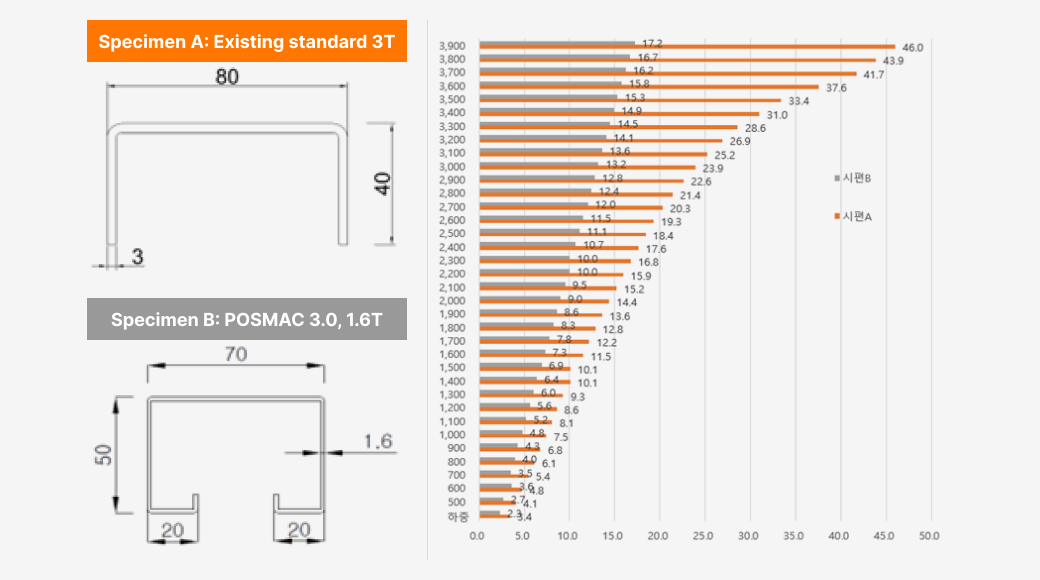

POSMAC Folded Section

High-Strength POSMAC 3.0 Structural Members: Maximizes internal space utilization / Significantly increases load-bearing strength

Comparative load-strength test between the standard 3T material and the POSMAC 3.0 (1.6T) replacement material shows: Improved performance by more than 2x under identical loading conditions

Interference Avoidance and Installation Ease

Designed to maintain horizontal alignment when inserting water tanks / No interference with HVAC equipment

Top Cover

Assembled using four panels, utilizing perforations for connecting Large Supports and brackets

Foam-board material allows screws to penetrate directly at the perforated points for easy fastening

Assembly begins from the center of the rack to prevent shifting to one side

Blocks external dust and contaminants

Containers

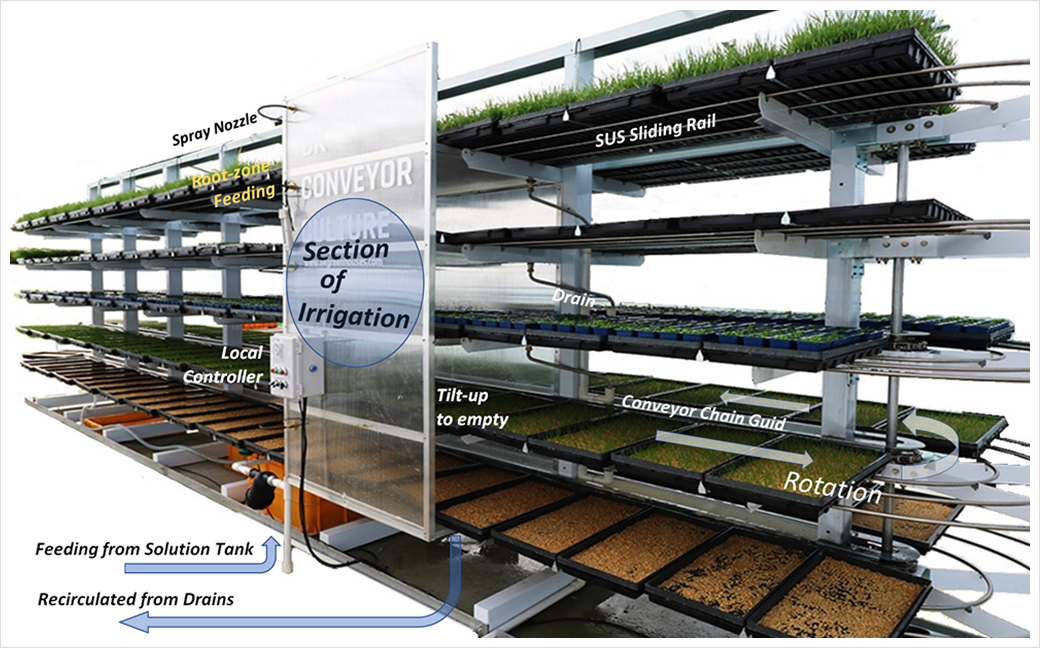

Container Farm

A plant-cultivation system unaffected by climate variation

Container farms require significantly less land than traditional agriculture, enabling large-scale farming even in space-limited urban environments. Regardless of unexpected climate changes, productivity remains stable. Because the interior environment is fully controlled and isolated, pests are eliminated, allowing pesticide-free, eco-friendly crop production.

Container-based cultivation enables fresh, uniform crops to be produced on demand. The stacked-layer design using plant-cultivation units offers far greater efficiency compared to traditional methods. Urban mass-production allows rapid delivery of fresh produce to customers while reducing transportation fuel use and CO₂ emissions, which aligns with modern eco-friendly lifestyle trends.

-

- Indoor farming

-

- LED accelerated cultivation

-

- Organic production

-

- Simple operation

-

- Automatic temperature & humidity control

-

- Mobile farming system

-

- High energy efficiency

-

- Resistant to wind and weather

KR

KR